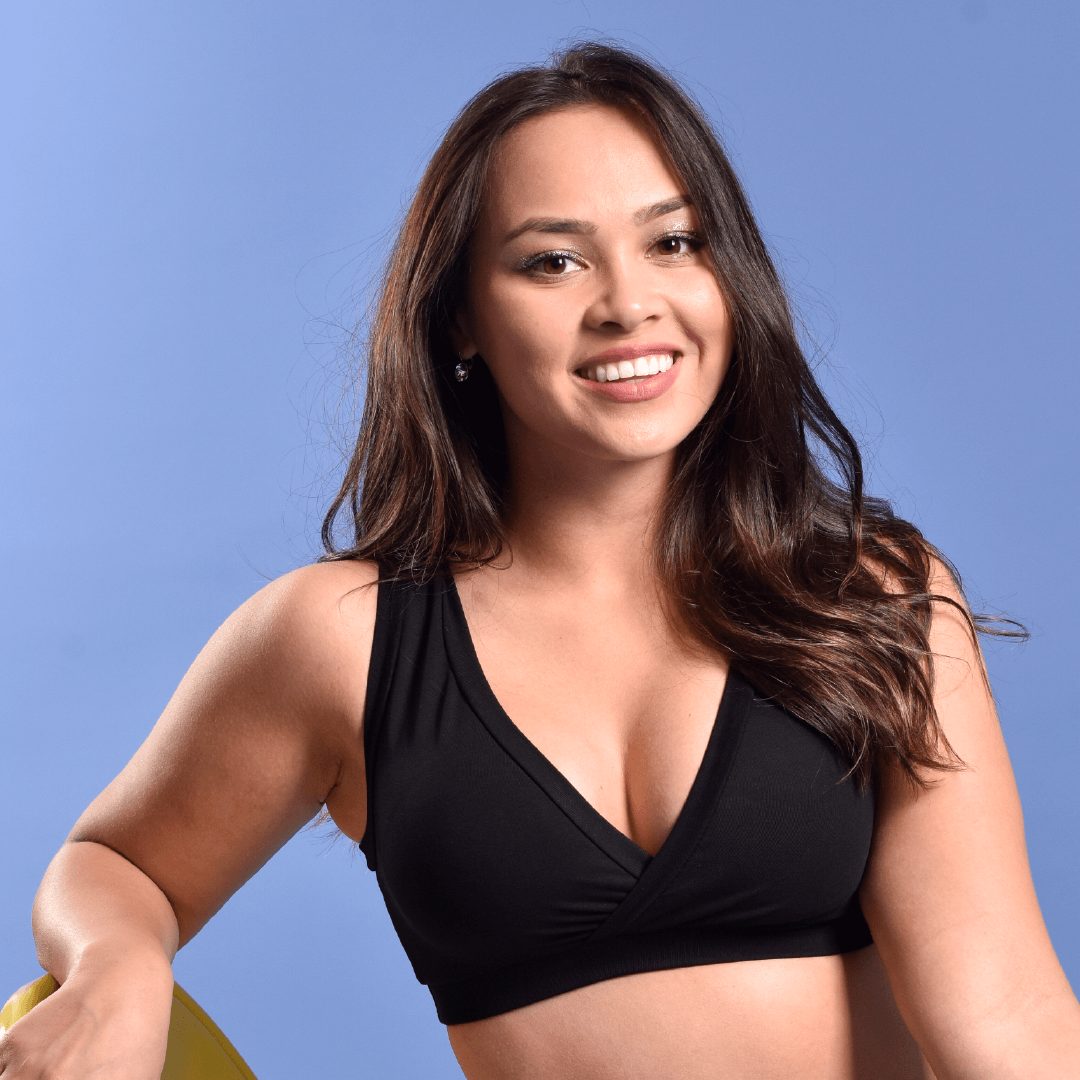

Over the last 4 years, our small team has grown alongside our wonderful customer base. One thing Kirsty and Ros remain passionate about is continuing to grow our manufacturing here in rural Perthshire and we now have a production team of 12 fantastic individuals. Every one of our Original Molke bras and mid-rise briefs are made here and so we thought we would take a little look at how we train our Molke machinists.

Despite most machinists starting with us with some level of sewing experience, we don’t expect them to start contributing to regular stock runs straight away. It usually takes several months before they are making a full contribution to production runs, so training does take time!

We are always striving to reduce our waste and everything we use as training materials would otherwise be surplus to requirement. The fabric comes from old designs that are no longer produced, or from offcuts that we can’t use for main production. This could be due to batch colour differences or slight print discrepancies. The threads we use are all leftover colours from discontinued designs. Even the elastic is joined together from offcuts of main production rolls, so as little as possible is wasted.

As we have really high quality standards, all of our new starters begin with consolidating core sewing skills and getting used to our industrial machines. This includes things such as practising coming on and off smoothly on old left over bands.

From there, they move on to our mid-rise briefs and practise the different stages of assembling these comfy creations. Once they successfully perfect those, they finally get to have a go at the Original Molke bra. As with the briefs, they have to master each section of the bra individually before moving onto the next stage. Along with training being overseen by our production manager, Mica, the team are very much encouraged to check their own work as they go, which ensures they understand our quality standards right from the beginning.

In terms of sizing, our machinists start with the mid-range sizing. This is usually M, L and XL bands and briefs. This is because, initially, these are the easiest sizes to work with. Before completing the training, they will have to cover the full range of sizes from an XS Stellar up to a 2XL Thunder.

As with anything at Molke, we like to make  bras and briefs that will bring you joy and our training items are no exception. With this in mind, we try and carefully select colour combinations from the material we have available, and make some wonderfully unique creations. These bras and briefs still have to go through quality checks and those that are deemed as seconds quality, will be added as Randoms into our Outlet section and sold at a discount. Due to the initial focus on the mid-sizes, this does mean that there are usually more of these available. We know this can be disappointing for those of us who don’t fit those sizes, but this is a necessary part of the training process.

bras and briefs that will bring you joy and our training items are no exception. With this in mind, we try and carefully select colour combinations from the material we have available, and make some wonderfully unique creations. These bras and briefs still have to go through quality checks and those that are deemed as seconds quality, will be added as Randoms into our Outlet section and sold at a discount. Due to the initial focus on the mid-sizes, this does mean that there are usually more of these available. We know this can be disappointing for those of us who don’t fit those sizes, but this is a necessary part of the training process.

In the final stage before graduating, all of our machinists are taught the secret of how to sew a little bit of Molke magic into everything they make - we won’t be telling you how we do that though!